Fuel feed gas

AGL Torrens Island: Torrens Island, S.A.

Scope:

– Gas skid B1, B2, B3 and B4 instrumentation upgrade.

– Instrument tubing.

– Instrument cabling run, installed and connected.

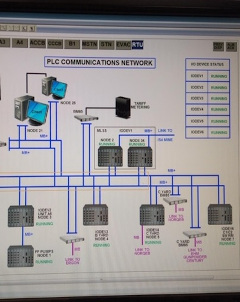

– Connection to Yokogawa plant wide control system.

– Cable ladder, marshalling cabinet construct and install, trenching, earthing and hazardous area connections.

Safety:

– Zero Lost Time Injuries.

– Zero Medical Treatment Injuries.

Completion:

November 2019.