Office and Administration Contact:

(p): +61 (0)3 9024 6223

(f) +61 (0)3 9011 9640

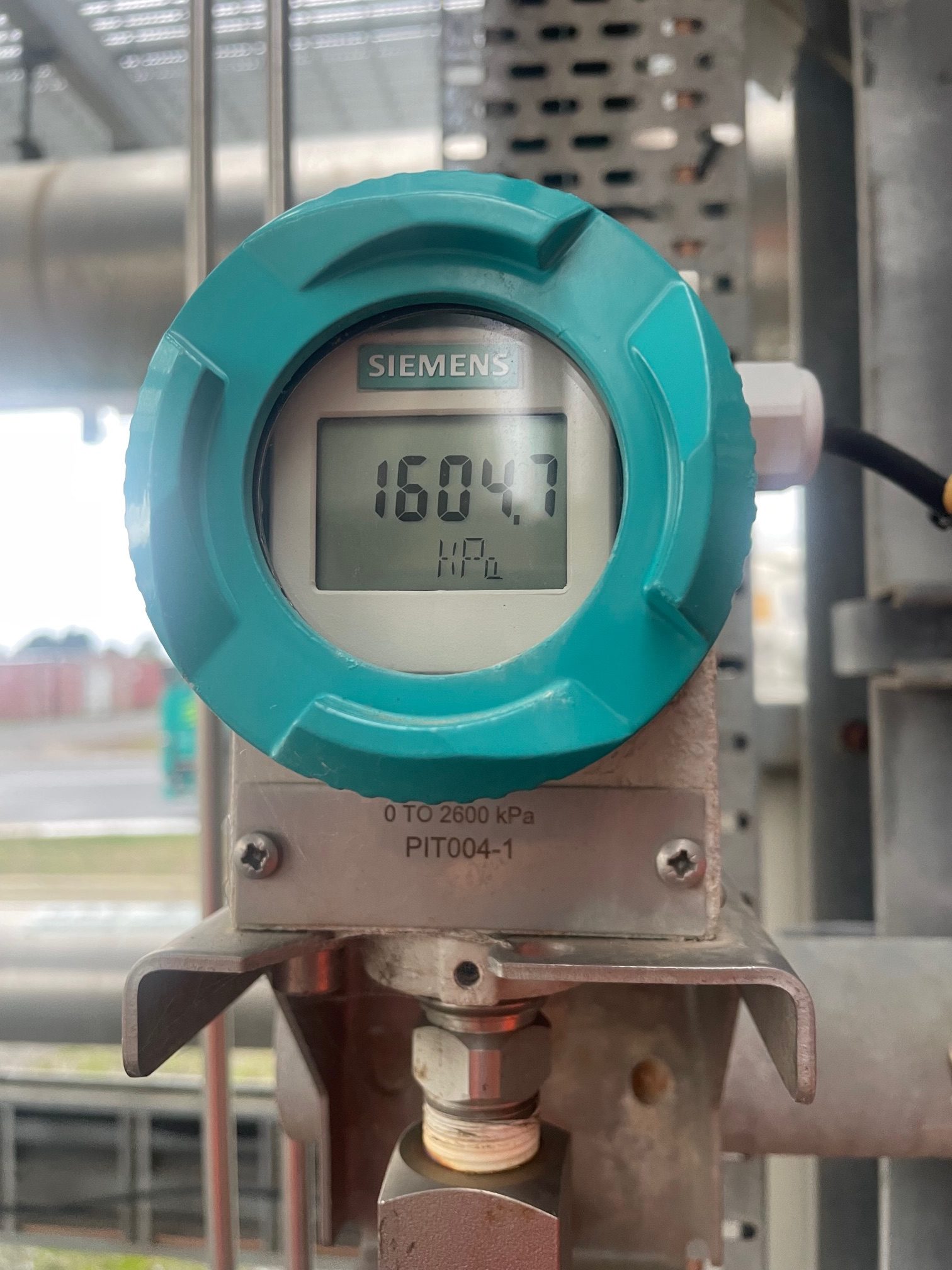

Process Control

Process Control, Instrument Calibration of CO2 Capture Plant - South Australia

Scope:

- From an instrument list access instruments.

-Check operation via calibration.

- Complete calibration certificates.

- Power up and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

September 2024.

Air Quality Monitoring - Medical Facility in Melbourne

Scope:

- Add sensors to locations that need to be monitored.

-Provide dashboard to look at live readings of sensors.

- Setup alerts for when thresholds are breached.

- Provide reports that are emailed daily (shows readings and alerts).

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

January 2024.

Process Control

Process Control, Instrument Calibration of CO2 Capture Plant - South Australia

Scope:

- From an instrument list access instruments.

-Check operation via calibration.

- Complete calibration certificates.

- Power up and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

October 2023.

LoraWAN Private Network Rollout

Install private LoraWAN network throughout Queensland

Scope:

- Develop safe installation methods.

- Install aerial and cabling on industrial rooftops.

- Test and provide quality documents to owner.

- Power up and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

August 2023.

Process Control

Process Control, Remote Wireless Link – South Australia

Scope:

- Enclosure electrical design.

- Interface to field instruments.

- Wireless link design and test.

-Commission and handover

.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

April 2023.

LoraWAN Private Network Rollout

Install private LoraWAN network throughout South Australia

Scope:

- Develop safe installation methods.

- Install aerial and cabling on industrial rooftops.

- Test and provide quality documents to owner.

- Power up and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

December 2022.

Control Room

Mobile Office Control Room Layout Design and Fitout – South Australia

Scope:

- Design layout of desks, workstations and enclosures.

- Design control network and server cabinets.

- Supply office, footings, fitout, Run power cables, fibre and control cables .

- Energise, test and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

August 2022.

Control Room

Mobile Office Control Room Layout Design and Fitout – Far North Queensland

Scope:

- Design layout of desks, workstations and enclosures.

- Design control network and server cabinets.

- Run power cables, fibre and control cables.

-Energise, test and handover.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

March 2022.

Process Control

Newcrest: Linde O2 Plant - PNG

Scope:

- Review current operations.

- Design and implement automatic start.

- To build and test create a fully functional software plant simulator.

- Commission and test on operating facility.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

December 2021.

Advanced Process Control

Newcrest: Oxygen Plants - PNG Optimization

Scope:

- Implement controls over three plants.

- Co-ordinate plants using APC strategy.

- Design all displays .

- Design all process control logic.

- Commission and test on operating facility.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

October 2021.

Process Control

Newcrest: Air Liquide O2 Plant - PNG

Scope:

- Review current operations.

- Design and implement automatic start.

- To build and test create fully functional software plant simulator.

- Commission and test on operating facility.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

April 2021.

Control Room

Stanwell, Mica Creek

Scope:

- Review current instrument and electrical requirements to relocate a control room.

- Assess risks.

- Scope control system upgrade requirements.

- Develop a cutover plan for a running power station.

- Determine budgets.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

March 2020.

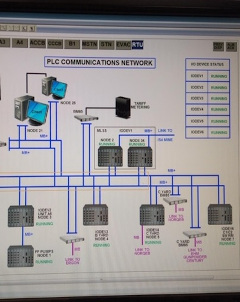

Power Generation

Stanwell: Mica Creek Power Station

Scope:

- Review current Citect MLSS and document operation.

- Review Schneider/Modicon PLC operation.

- Relocate logic to Plant Wide control Systems.

- Relocate displays from Citect to Plantwide control system.

- Commission and test on operating facility.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

June 2020.

Fuel feed gas

AGL Torrens Island: Torrens Island, S.A.

Scope:

- Gas skid B1, B2, B3 and B4 instrumentation upgrade.

- Instrument tubing.

- Instrument cabling run, installed and connected.

- Connection to Yokogawa plant wide control system.

- Cable ladder, marshalling cabinet construct and install, trenching, earthing and hazardous area connections.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

November 2019.

Gas turbine electrical generation

AGL Power Station: Somerton, VIC.

Scope:

- Electrical and Instrument disconnection and removal for mechanical access.

- Instrument storage for duration of generator overhaul.

- Instrument installation and connection for starup and commissioning.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

July 2019.

Wind Turbine

Hepburn Wind: Hepburn, Victoria

Scope:

- Integrate InformDB monitoring system into existing controls.

- Configure cloud database connections.

- Configure key alerts for remote monitoring.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

February 2019.

Mining Explosives Manufacturing

Dyno Nobel: Moranbah, QLD.

Scope:

- Control system engineering assistance.

- Foxboro I/A Series Distributed Control System, Triconex Safety System.

- System administration assistance and configuration changes.

Safety:

-Zero Lost Time Injuries.

-Zero Medical Treatment Injuries.

Completion:

Ongoing.

Gas turbine return to service

Stanwell Power Station: Mica Creek

Scope:

- Instrumentation inspection and calibration.

- Vibration system repair.

- GE Mark V control system check.

- Foxboro DCS and ancillary system check.

- Turbine run up and commission assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

September 2018.

Fuel gas inlet to turbine

Stanwell Power Station: Mica Creek

Scope:

- Complete gas skid inspection.

- Upgrade equipment.

- Upgrade earthing.

- Upgrade Hazardous Area Dossier.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

August 2018.

Plantwide service during planned maintenance

Air Liquide Oxygen Plant: Port Pirie

Scope:

- Pressure and temperature field calibrations.

- Rectify faults.

- Issue calibration certificates.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

August 2018

Gas turbine return to service

Stanwell Power Station: Mica Creek

Scope:

- Instrumentation inspection and calibration.

- Vibration system repair.

- GE Mark V control system check.

- Foxboro DCS and ancillary system check.

- Turbine run up and commission assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

September 2018.

Instrumentation Calibration and Control

System Test Prior to Return to Service

Stanwell Power Station: Mica Creek

Scope:

- Calibrate gas turbine instruments.

- Completion of inspection and test.

- Adjust control system logic as required.

- Assist in commissioning.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

March 2018.

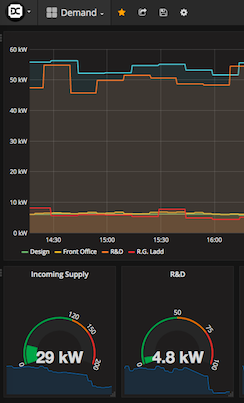

Electrical Switchboard Manufacturers

Decon Corporation: Melbourne

Scope:

- Design and construct energy monitoring and analytics information system.

- Installation supervision.

- Configure and install the InformDB Technology Stack.

- Design and deliver display dashboards.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

January 2018.

Process instrumentation and tubing

Stanwell: Queensland

Scope:

- Install water analyzers.

- Source and install process instrumentation.

- Complete wet rack tubing.

- Commissioning assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

August 2017.

Field wiring for DCS Serial Gateways Upgrade

Stanwell: Queensland

Scope:

- Install and energize control enclosures.

- Run serial cables for all communication gateways.

- Run fibre optic cabling for upgraded communications links.

- Commissioning assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

July 2017.

Air Compressor and Dryer Electrical Integration

AGL: South Australia

Scope:

- Project management, enclosure manufacture and trades supervision.

- Field ladder and electrical cabling installation.

- Supervisory controls design.

- Integration into the plantwide control system.

- Commissioning assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

June 2017.

Gas turbine emissions measurement and reporting

Citic Pacific: Western Australia

Scope:

- Addition of 6 more emissions stacks expanding our

February 2016 installation.

- Project management, server configuration and

supply, emissions information systems.

- Hourly, daily and monthly emissions reports using

the informDB Technology Stack.

- Communications and interfacing to the

ABB gas analyzers.

- Linkage to the plantwide control systems.

- Quality documentation including drawings.

- On site commissioning.

Safety:

-Zero Lost Time Injuries.

-Zero Medical Treatment Injuries.

Completion:

May 2017.

Major shutdown services -

ammonium nitrate production plant

Incitec Pivot Limited -

Dyno Nobel Moranbah Queensland

Scope:

- DCS and Safety Instrumented System (SIS) proof checking.

- Maintenance and update of quality test sheets and records.

- Rectification and update works where required.

- Hazardous area.

Safety:

- Zero Loss Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

April 2017.

Radar level integration via wireless network to plantwide control system

AGL: South Australia

Scope:

- Project management, enclosure manufacture and trades supervision.

- Field conduit and electrical cabling installation.

- Electrical design for radar gauge level automation.

- Hazardous area design and installation.

- Drawing office completion.

- Custom mechanical instrument stand and cable way manufacture.

- Commissioning assistance.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

February 2017.

Demineralisation plant control system and

cabling upgrade.

AGL: South Australia

Scope:

- Legacy control system documentation and upgrade (Siemens platform).

- Addition of a touch screen user interface.

- Project management, enclosure manufacture, control system design and trades supervision.

- Enhanced communications via fibre optic installation.

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

May 2016.

GPS time synchronization receiver installed

and connected to the Plant Wide

control system

Stanwell: Far North Queensland power station

Scope:

- Design and issue drawings.

- Procure equipment, stage and test.

- Design lightning protection circuits and select equipment.

- Complete a site installation and quality plan.

- Install GPS receiver and lightning arrestors on site,

run cabling to Plant Wide control system.

- Configure software in control system to synchronize time automatically.

- Test and hand over

Safety:

- Zero Lost Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

March 2016.

Gas turnbine emissions measurement and reporting

Citic Pacific: Western Australia

Scope:

- Project management, server configuration and supply,

emissions information systems.

- Hourly, daily and monthly emissions reports using the

informDB Technology Stack.

- Communications and interfacing to the ABB gas analyzers.

- Linkage to the plantwide control systems.

- Quality documentation including drawings.

- On site commissioning.

Safety:

-Zero Lost Time Injuries.

-Zero Medical Treatment Injuries.

Completion:

February 2016.

Assistance with Foxboro plant wide control

system configuration

Cardno / Newcrest Mining: Papua New Guinea,

New Ireland Province (Lihir Island)

Scope:

- Control system engineering assistance.

- Foxboro I/A Series Distributed Control System.

- Specification and configuration changes.

Safety:

-Zero Lost Time Injuries.

-Zero Medical Treatment Injuries.

Completion:

Ongoing.

Oil & Gas processing emissions monitoring

Exxon: Longford Gas Processing Plant

Scope:

- Project management, server configuration and supply,

emissions information systems.

- Hourly, daily and monthly emissions reports using the

informDB Technology Stack.

- Communications and interfacing to the ABB

gas analyzers.

- Linkage to the plantwide control systems.

- Quality documentation including drawings.

- On site commissioning.

Safety:

-Zero Lost Time Injuries.

-Zero Medical Treatment Injuries.

Completion:

Factory testing February 2016. Commissioning December 2016

Exxon: Fuel Terminal South Australia

Scope

- Project management, electrical design, network design

and trades supervision.

- Cabling and Fibre optic installation.

- Manufacture and supply of server rack.

- Upgrade of workstation software.

- Commissioning.

- Training

Safety:

- Zero Loss Time Injuries.

- Zero Medical Treatment Injuries.

Completion:

June 2015.

Office and Administration Contact:

(p): +61 (0)3 9024 6223

(f) +61 (0)3 9011 9640